SABIC Develops and Validates Thermal Runaway Barrier Solution for Electric Two-Wheeler Batteries

25/08/2023

Global manufacturers, especially those in India and China, are experiencing an increased need to address fire safety concerns around electric two-wheeler (2W) battery systems. Following several fire incidents involving 2W batteries, the industry is looking for solutions that go beyond what’s currently available, especially as current options are experiencing issues with phase change materials leaking and may not be effective.

Leveraging its existing flame retardant STAMAX™ resin technology, SABIC has developed a novel thermal runaway (TRA) barrier solution to increase the fire safety of 2W batteries.

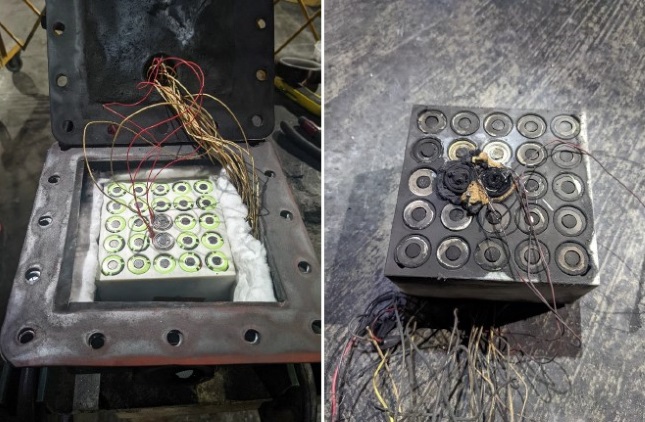

When this TRA barrier with FR STAMAX resin encounters fires or high heat, small char-like indentations immediately begin to form. Within minutes, these char-like additions act as an expansion layer that serves as a barrier to the battery cell, meaning that if one cell is compromised, it will not spread, and the other battery cells will remain intact.

Testing at UL

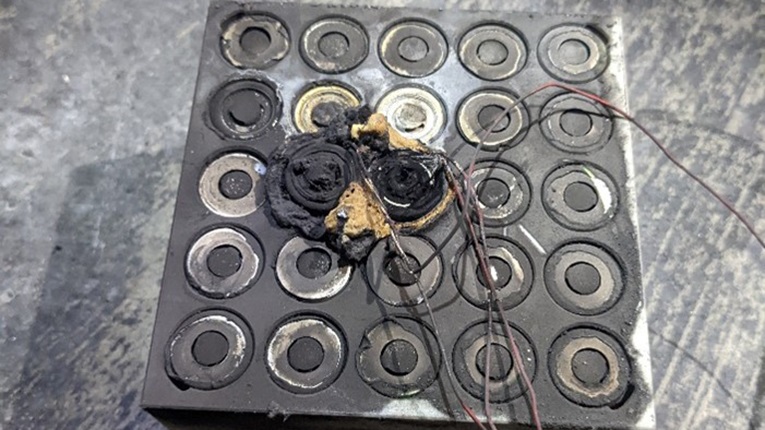

In testing the TRA barrier solution, SABIC worked with the Underwriters Lab (UL) to validate its performance. The test involved placing 25 standard 18650 cylindrical cells in a box and separating them with 2 millimeters of the barrier component with FR STAMAX 30YH570 resin. Two of the middle cells were then triggered to initiate thermal runaway.

Afterwards, the remainder of the 23 cells were observed for damage. The result: all were found to be working safely with zero thermal penetration or impairment.

SABIC FR STAMAX 30YH570 resin secured an official verification mark from UL for its thermal and mechanical performance during a thermal runaway scenario.

Advantages for Partners

SABIC’s unique injection molded, single-piece TRA barrier solution offers numerous advantages for EV batteries, including:

- Easy disassembly

- Ease of manufacturability - large production volumes with cycle times of less than one minute

- Easy scalability to fit a variety of size and energy capacities of cylindrical cell batteries

- Lighter solution as compared to traditional metals

- Reduced cost

- Reduced weight

- Enhanced fire safety

- Ease of recyclability with a thermoplastic solution